After three years of hard work, the ZDZW closes strong, making substantial progress in advancing the manufacturing industry through innovative inspection solutions and the development of new business models.

The ZDZW project was an ambitious European effort funded under the Horizon Europe programme with the goal of advancing “zero-defect” (ZD) and “zero-waste” (ZW) manufacturing across key industrial sectors. At its core, the project addressed the twin challenges of improving product quality (minimising defects) and reducing material waste in production processes by deploying advanced non-destructive inspection (NDI) technologies, digitalisation and business model innovations.

Why is ZDZW relevant?

In today’s manufacturing landscape, achieving zero defects and zero waste is a major competitive and sustainability advantage. The ZDZW project tackled this by combining advanced inspection technologies with digitalisation and business innovation.

Non-destructive inspection techniques are pivotal for achieving the dual goals of zero-defect and zero-waste manufacturing by enabling manufacturers to optimise their production processes and minimise material wastage. By doing so across diverse production processes and sectors, ZDZW’s outcomes can have a broad ripple effect in improving quality, lowering costs, reducing environmental footprint, and enabling smarter factories.

The ZDZW project was an ambitious European effort funded under the Horizon Europe programme with the goal of advancing “zero-defect” (ZD) and “zero-waste” (ZW) manufacturing across key industrial sectors. At its core, the project addressed the twin challenges of improving product quality (minimising defects) and reducing material waste in production processes by deploying advanced non-destructive inspection (NDI) technologies, digitalisation and business model innovations.

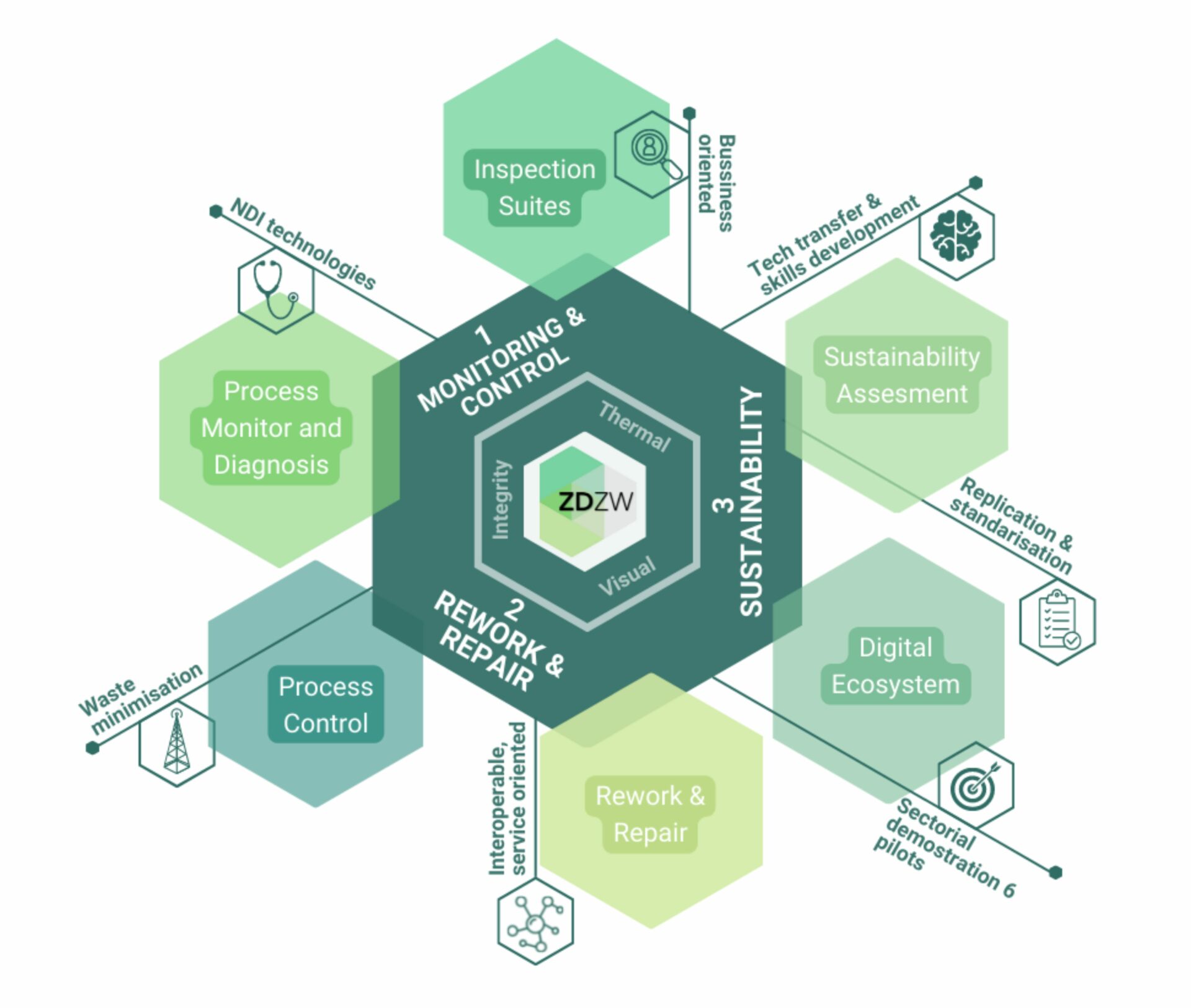

Objectives & Solutions

Key objectives:

- Develop interoperable inspection solutions (integrity inspection, visual inspection, thermal inspection) for inline or near-line evaluation of key product parameters.

- Introduce new business models (Inspection-as-a-Service, subscription, pay-per-use) to make the technologies accessible and scalable.

- Provide consultancy and training services to facilitate industrial uptake, including skills-development strategies.

- Offer sustainability assessments and digital factory solutions to identify efficient routes to waste reduction.

Consortium & Scope

About the ZDZW NDI Solutions

The ZDZW project developed a portfolio of 11 innovative solutions, strategically organized into three inspection suites. Each suite addresses a different dimension of manufacturing quality assurance, visual, thermal, and integrity inspection, covering a wide range of industrial processes and materials.

- Integrity inspection suite: Monitor and control key processes like induction hardening, ensure internal component integrity with acoustic emission-based inspections, detect sub-surface defects using MIR-OCT, and automate the inspection of critical welded joints. Experience precision, innovation, and efficiency redefined for the future of manufacturing.

- Visual inspection suite: Ensure thorough defect detection in every part introducing cutting-edge techniques like multi-camera 3D scanning and artificial vision. Overcoming limitations, the services prioritise accessibility, providing easily comprehensible defect location information. Elevate manufacturing efficiency with our precise and streamlined visual inspection solutions.

- Thermal inspection suite: Obtain real-time quality control for thermoforming, sealing, and welding. Through in-line monitoring and control via Digital Twins and top-tier AI algorithms, these solutions minimise process variability, offering a streamlined approach to thermal manufacturing quality. Benefit from immediate defect detection and eliminate complexities in reworking defective parts.

Take a closer look at all 11 ZDZW Solutions.

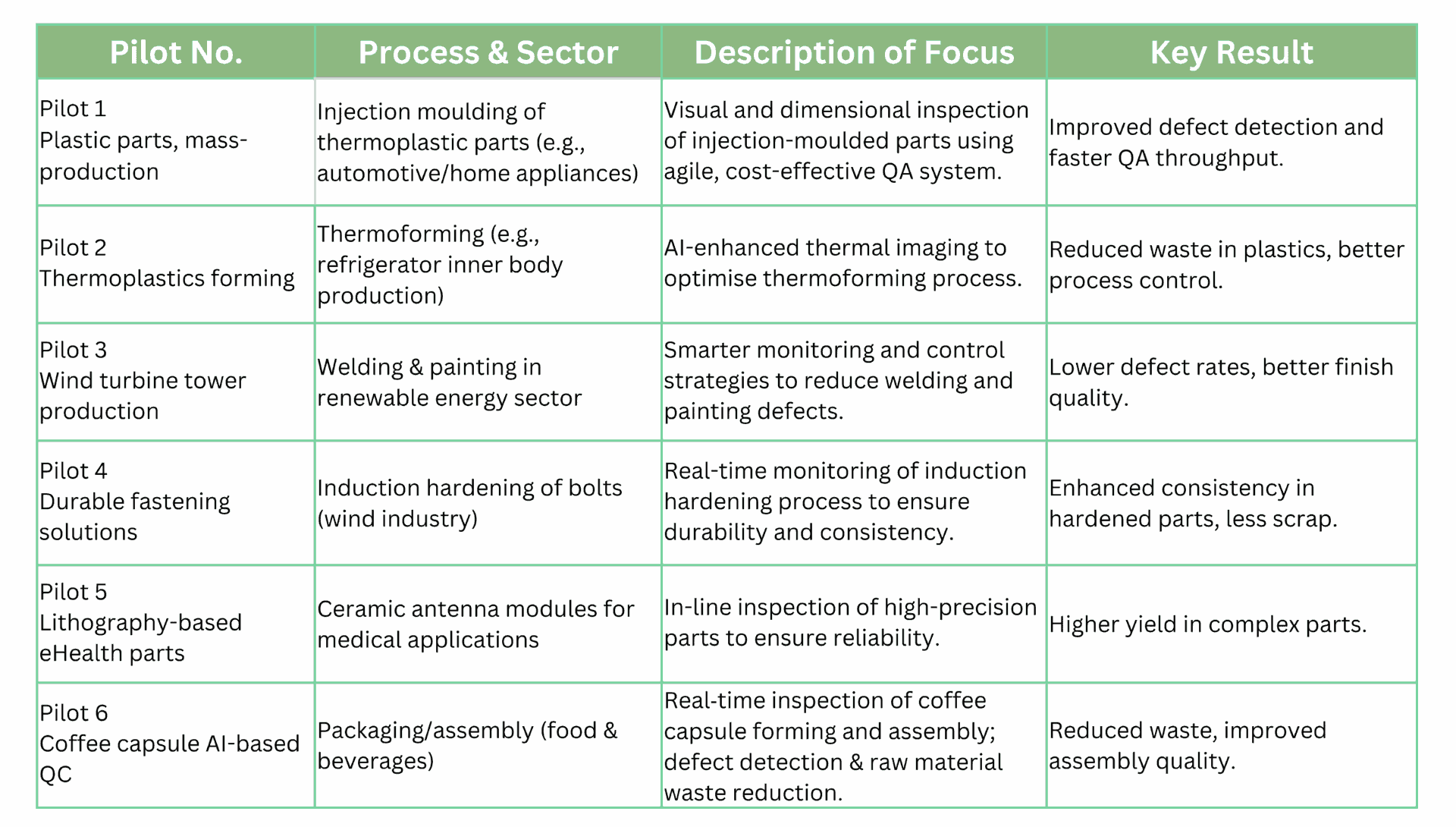

Pilot Use-Cases & Results

A core part of the ZDZW project was six industrial pilots spanning different manufacturing processes and sectors.

Here’s a summary:

Major Achievements & Impact

The ZDZW project made substantial progress in advancing the manufacturing industry through innovative inspection solutions and the development of new business models. By focusing on cutting-edge technologies and scalable adoption strategies, the project enabled significant improvements in production efficiency and sustainability.

- The launch of the ZDZW Marketplace: enabling broader deployment of the inspection solutions across the manufacturing industry, with flexible business models.

- Successfully demonstrating ZDZW solutions in six diverse industrial pilots: from plastics forming to wind turbine manufacturing and food packaging.

- Advancing the state-of-the-art in non-destructive inspection technologies (integrity, visual, thermal) and integrating them into digital platforms, supporting Industry 4.0.

- Promoting new business models (Inspection-as-a–Service) which can lower the barrier to entry for SMEs and enable scalable adoption.

- Enabling sustainability benefits through waste reduction, improved process efficiency and higher first-time-right production

Looking Ahead

Although the project formally closed in August 2025, the legacy continues:

- The solutions developed will be available on many platforms, such as Techfinders and can be tested and/or adopted by industry actors.

- The consortium’s skills-development and training strategy aims to support ongoing industrial uptake.

- The digital inspection services and business models pioneered can serve as templates for future manufacturing innovation.

Fundingbox involvement

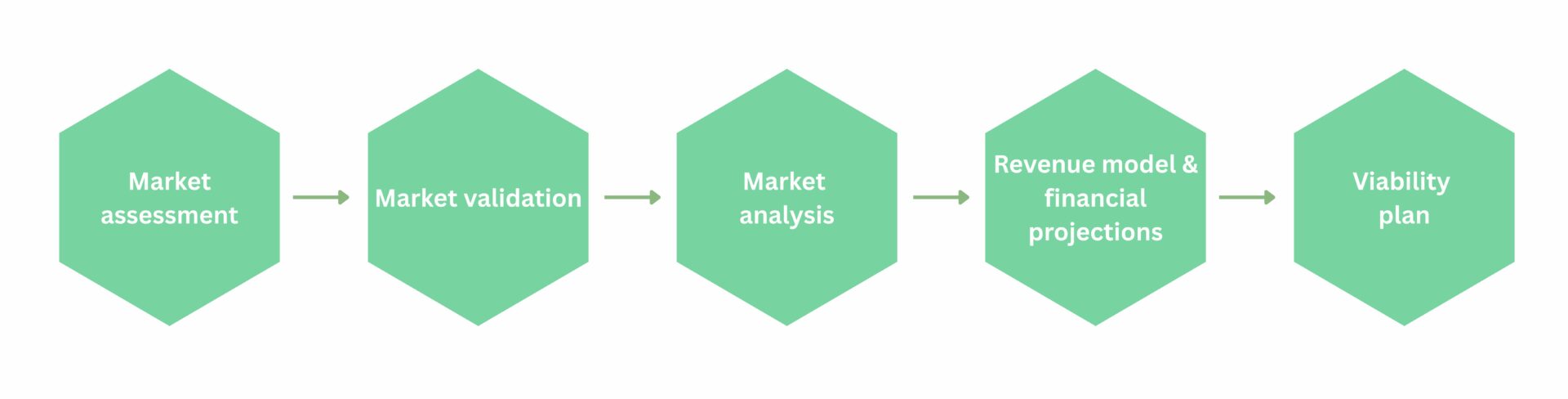

Fundingbox was actively involved in the ZDZW project through its Tech Transfer cluster, where it played a key role in leading the exploitation plan. This included guiding the go-to-market strategies and helping the project results become market-ready through Techfinders.

The go-to-market process followed the following key stages:

In terms of achievements, these were Fundingbox contributions:

- Defining 11 value propositions for each solution, ensuring that each solution addressed clear market needs.

- Creating 4 buyer personas, targeting the adequate audience for each solution.

- Launch the Beta Testing Campaign, engaging 8 early adopters who provided valuable insights for the project’s development.

- A comprehensive market analysis, providing an in-depth understanding of market dynamics and trends.

- 11 Financial projections were made for all project results and the ZDZW Marketplace, ensuring that the economic viability of each solution was clearly outlined.

- Developed revenue model and cost structure for the 11 results and the marketplace, giving a clear financial framework for the solutions’ commercialization.

- Market entry recommendations, alongside a structured go-to-market timeline, offering a strategic roadmap for the solutions to successfully enter the market.

Final Remarks

The ZDZW project stands as a compelling example of how European industry and research can collaborate to drive tangible advancements in manufacturing quality, efficiency, and sustainability. Through its comprehensive approach, the project has brought together a diverse consortium of partners from across Europe, including industry leaders, research institutions, and SMEs, all working towards a common goal of revolutionising manufacturing processes. By showcasing real-world pilots across a variety of industries, ZDZW has demonstrated the practical application and benefits of its innovative solutions, from plastics forming to wind turbine manufacturing and food packaging.

The project’s deployment of cutting-edge non-destructive inspection technologies such as visual, thermal, and integrity inspection, has significantly advanced the state-of-the-art in quality control. These technologies have been seamlessly integrated into digital platforms, supporting the transition to Industry 4.0 and enhancing the overall efficiency of manufacturing processes. Additionally, ZDZW has introduced innovative business models, including Inspection-as-a-Service, which lower the entry barriers for SMEs and facilitate scalable adoption of these solutions across the manufacturing sector.

Through these efforts, ZDZW has laid a solid foundation for the future of smarter, leaner, and more sustainable manufacturing systems. By reducing waste, improving first-time-right production rates, and enhancing process efficiency, the project has not only contributed to the competitiveness of European manufacturing but also set a new standard for sustainability in industrial production.

The ZDZW project has received funding from the European Union’s Horizon Europe programme under grant agreement No 101057404.

About the author

María Paez Guerrero

Tech Transfer Department Marketing Coordinator and Techfinders Product Owner

María leads the marketing at the Technology Transfer department and drives product strategy and marketing at Techfinders, helping manufacturing developers craft compelling value propositions for their solutions and connect with a strong online community. Her work ensures that SMEs can seamlessly access and adopt innovative technologies.

About the author

Andrea Puentes

Former Fundingboxer

Proven Business Administrator with 7+ years of experience in diverse fields, including marketing and trade marketing for multinational companies in sectors such as pharma and consumer goods, as well as consulting for sports and entertainment in areas of sponsorships, partnerships, and research.