Written by: Ola Skalska

How “Shoes in Circle” is redefining shoe manufacturing with circular knitting, automation, and parametric design for a greener, more personalized future.

Introduction

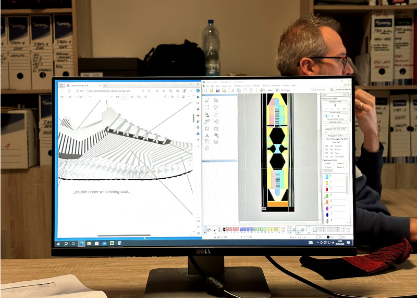

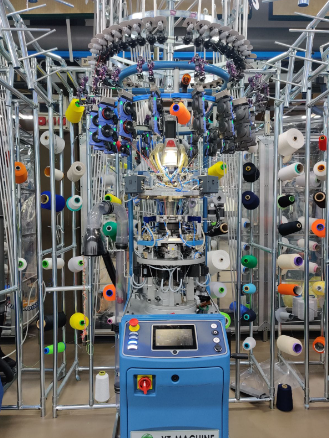

Forget traditional shoemaking! The future of footwear is circular, automated, and customizable. The Shoes in Circle experiment funded within the Better Factory project that Fundingbox partners in, spearheaded by Polish manufacturer Tapi-1 is transforming how shoes are made. By merging cutting-edge tech co-developed with Studio GF&L like circular knitting, parametric design, and cobots, they’re paving the way for a more sustainable and innovative industry.

The Problem with Traditional Shoemaking

Conventional shoe manufacturing is a messy, resource-intensive process.

It is wasteful, as leather cutting generates significant waste, even though leather itself is an upcycled material. The customization requires time-consuming metal die-cuts for each element and size. On top of that, multiple steps, various machines, and extensive manual labor complicate the process and workers are exposed to harmful leather dust and chemicals during production.

Shoes in Circle is tackling these challenges head-on:

- Waste Reduction: Circular knitting, an additive process using yarn, eliminates virtually all cut-out waste compared to traditional methods.

- Simplified Customization: Parametric design and circular knitting enable rapid, easy customization without the need for metal die-cuts.

- Automated Manufacturing: Cobots (collaborative robots) automate tasks like roughing and cement application, reducing worker exposure to hazards.

- Optimized Production: IoT sensors and software provide real-time insights into machine performance, streamlining the manufacturing process.

Innovative concept, new players

This innovative approach yields numerous benefits:

Benefit | Details |

| Waste Reduction | 30kg less harmful chemical cleaner |

| Resource Efficiency | 1mWh lower electricity usage per year |

| Employee Empowerment | 2 roles boosted to digital expertise |

| Safety Improvements | Reduced exposure to dangerous leather dust |

| New Revenue Streams | Potential through innovative product offerings |

In the case of Shoes in Circle, it was clear from the beginning that innovation needs to emerge from the unique approach to planning and design. The manufacturer collaborated with an artist (ANKA WALICKA PROJEKT) who brought her catwalk expertise to the project, designing concept footwear fit for circularity. These creations demonstrated not only the potential of this new manufacturing model but also sparked inspiration for the future of footwear fashion.

The Future of Footwear is here

Shoes in Circle is revolutionizing shoe manufacturing, paving the way for a more sustainable, efficient, and personalized industry. By embracing circularity, automation, and design innovation, they’re proving that style and sustainability can go hand in hand.

Here is a Step-by-Step Guide for Adopting Circular Practices in your business:

Step | Circular Practices /Actions |

| Assessment | Evaluate current practices and identify areas for improvement. |

| Strategy Development | Formulate a circular economy strategy tailored to your business. |

| Material Innovation | Source sustainable materials and develop eco-friendly designs. |

| Process Optimization | Implement lean and green manufacturing processes. |

| Partnerships and Alliances | Collaborate with stakeholders across the supply chain. |

| Consumer Engagement | Educate consumers on the benefits and availability of sustainable options. |

| Monitoring and Evaluation | Continuously monitor progress and adapt strategies as needed. |

Are you a manufacturer ready to step into the future of footwear? Contact FundingBox to learn more about how you can leverage EU funding and innovate your manufacturing business.